Sealing Wax for Mailing: How to Choose the Right Wax for Beautiful, Mail-Safe Seals

What Is Sealing Wax?

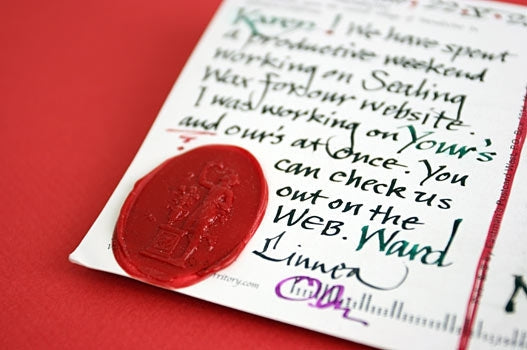

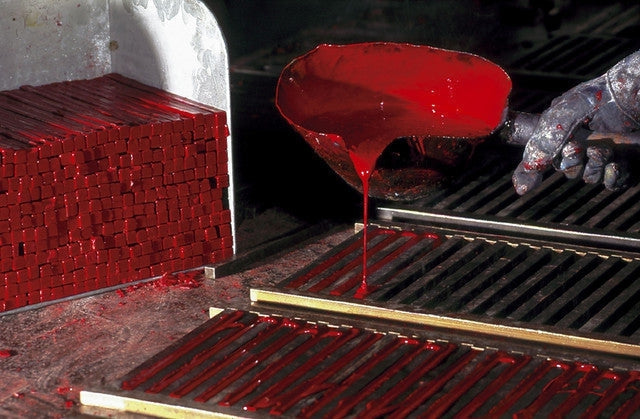

Sealing wax is a meltable wax blend used to create decorative wax seals on envelopes, wedding invitations, stationery, and crafted items. While traditional sealing wax was historically made from wax, shellac, and resins for hand-delivered correspondence, modern sealing wax includes flexible formulations specifically designed to survive mailing.

If you plan to send your envelopes through the postal system, choosing the right type of sealing wax is essential. Flexible sealing wax for mailing is engineered to resist cracking during automated sorting and handling, making it suitable for wedding invitations, save-the-dates, and everyday mail that still deserves a beautiful finish.

👉 Flexible, Mailable Sealing Wax Collection

Sealing Wax at a Glance: Which Type Is Right for You?

Traditional Sealing Wax

-

Best for: Display pieces, keepsakes, hand-delivered invitations

-

Finish: Crisp detail, often glossy, classic vintage appearance

-

Durability: Brittle and prone to cracking

-

Mailing suitability: ❌ Not recommended for postal use

Traditional sealing wax offers beautiful detail but contains a higher shellac content, making it breakable under pressure. For this reason, it’s best reserved for decorative projects or invitations that won’t be mailed.

Flexible Sealing Wax (Best for Mailing)

-

Best for: Mailed invitations, save-the-dates, greeting cards

-

Finish: Slightly softer detail with excellent durability

-

Durability: Designed to flex slightly instead of cracking

-

Mailing suitability: ✅ Yes — ideal for USPS and courier shipping

Flexible sealing wax is specially formulated to withstand rough handling.

👉 Flexible, Mailable Sealing Wax Collection

Wax Beads

-

Best for: Bulk projects, custom color mixing, precise portion control

-

Finish: Varies depending on wax formulation

-

Durability: Depends on whether the beads are traditional or flexible

-

Mailing suitability: ✅ Yes

-

Wax beads are melted in a spoon and are ideal for mixing custom colors or maintaining consistency across large projects. For mailed items, be sure to choose beads made with a flexible wax formula.

👉 Mailable Wax Bead Collection

How to Choose Sealing Wax for Mailing

1. Intended Use

-

For mailing: Always choose flexible sealing wax designed to survive postal handling

-

For display or keepsakes: Traditional wax offers higher detail

-

For high-volume projects: Glue gun sealing wax provides speed and consistency

👉 Glue Gun Sealing Wax Collection

2. Application Method

Wick Wax Sticks

Require an open flame and offer a romantic, old-world experience.

Glue Gun Sealing Waxes

Provides consistent temperature control, clean application, and excellent durability. Ideal for beginners and for producing multiple seals efficiently.

Wax Melting Spoon

Perfect for wax beads or broken stick pieces. Portable, versatile, and great for color mixing.

👉 Wax Melting Tools & Accessories

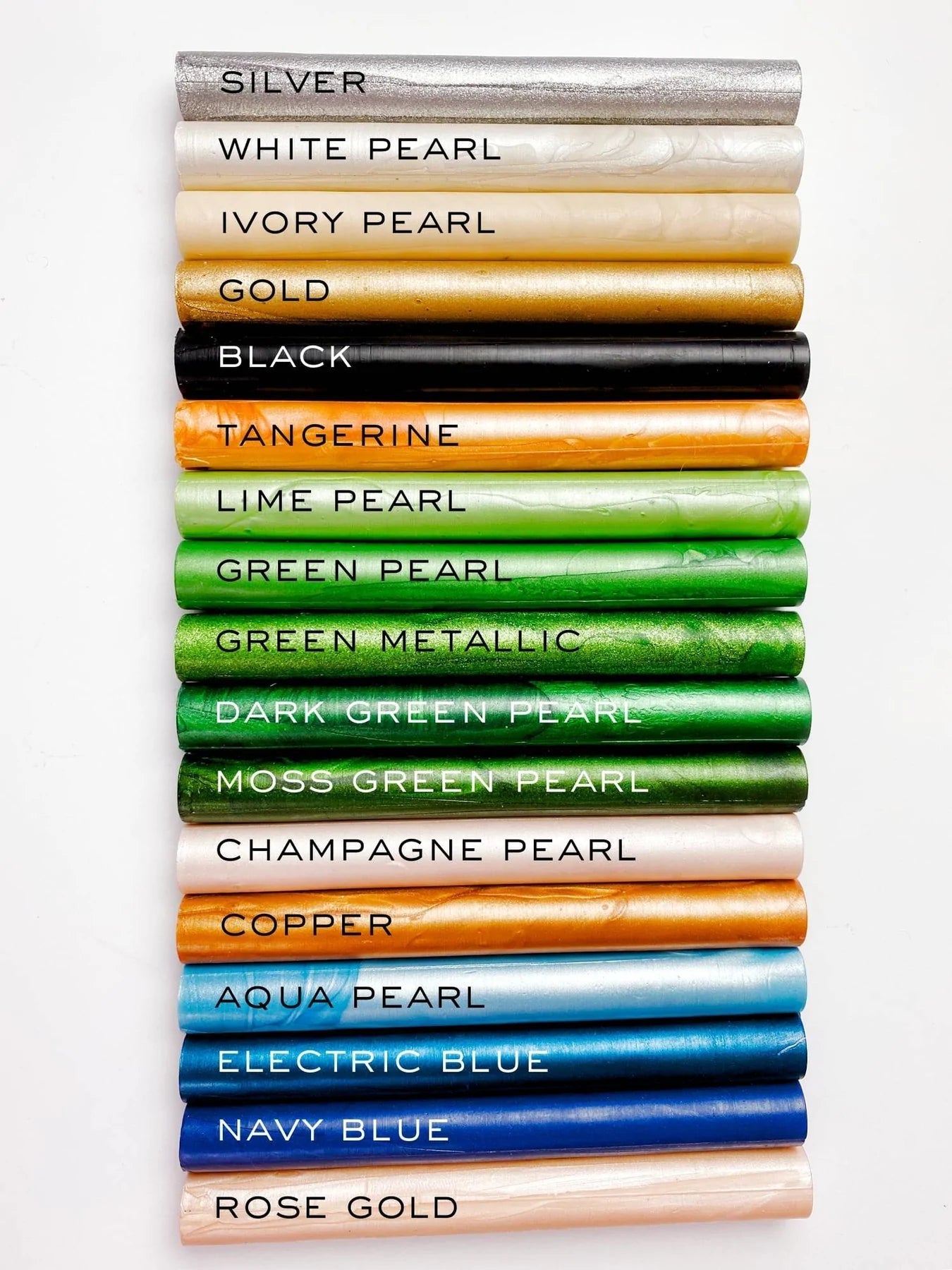

3. Color and Finish

Sealing wax is available in a wide range of colors and finishes, from classic reds and metallic golds to modern pastels and matte tones.

-

Metallic finishes: Gold, silver, copper — elegant and eye-catching

-

Pearl or shimmer: Soft iridescence for romantic designs

-

Matte colors: Clean, modern aesthetic

-

Custom blends: Mix wax beads to create one-of-a-kind shades

Wax beads are especially helpful for achieving custom or marbled color effects.

Common Questions About Sealing Wax for Mailing

Will sealing wax survive the mail?

When you use flexible sealing wax. Flexible formulations are designed to withstand most postal machinery and handling. Traditional wax may crack or break during automated sorting. For added protection, some customers choose hand-canceling at the post office.

How many seals does one wax stick make?

A standard wax stick (approximately 4 inches) typically produces 5–7 seals, depending on stamp size. Wax beads allow for more precise portioning, usually 3–5 beads per seal.

Can I mix sealing wax colors?

Absolutely. Wax beads are ideal for color mixing. Melt multiple colors together to create custom shades or partially mix for marbled effects.

You can also alternate colors of glue gun sealing wax sticks in the glue gun. The melting colors will mix and swirl together.

What temperature should sealing wax be?

Sealing wax melts between 160–180°F (71–82°C). Glue guns on a low setting or other electric wax melting tools help maintain an even temperature. Overheating can cause bubbling, discoloration, or separation.

How do I prevent wax from sticking to my stamp?

We offer a non-stick stamp release packaged in a reclosable tin with a sponge applicator. Simply dab your stamp before each impression. Ice water baths between seals can also help prevent sticking.

Shop Sealing Wax for Mailing with Confidence

At LetterSeals.com, we design and test sealing wax with real-world use in mind — especially mailing. Our flexible sealing wax is selected for clean melts, consistent color, and reliable performance through modern postal systems.

Whether you’re sending wedding invitations, holiday cards, or everyday correspondence, you’ll find mail-safe sealing wax in flexible sticks, glue gun formats, and wax beads — all curated for quality and ease of use.

![primary_cropped_847d8fe5-734c-45b6-9456-843d8e6e470c[product-name]-LetterSeals.com](http://www.letterseals.com/cdn/shop/files/primary_cropped_847d8fe5-734c-45b6-9456-843d8e6e470c.jpg?v=1614345763&width=740)

![primary_cropped_847d8fe5-734c-45b6-9456-843d8e6e470c[product-name]-LetterSeals.com](http://www.letterseals.com/cdn/shop/files/primary_cropped_847d8fe5-734c-45b6-9456-843d8e6e470c.jpg?v=1614345763&width=220)

Leave a comment